Valve Control Systems and Automation

Valves regulate the flow and pressure of liquids, gases, gels, powders and other substrates as they move through piping systems. Valve controllers and/or actuators manage the valves by adjusting their positions as needed.

Valves regulate the flow and pressure of liquids, gases, gels, powders and other substrates as they move through piping systems. Valve controllers and/or actuators manage the valves by adjusting their positions as needed.

Valve control systems can be either manual or automatic. Manual valves use human operators to monitor conditions and physically adjust the valves as needed. Conversely, automatic valve controllers adjust to changing conditions independently without the intervention of human operators.

Erdmann Corporation has the knowledge and longstanding experience to update and automate existing manual controllers or design entirely new automated valve control systems.

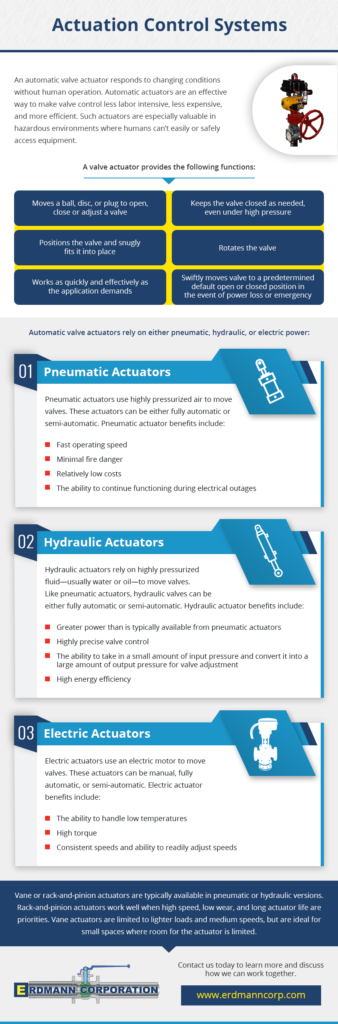

Actuation Control Systems

An automatic valve actuator responds to changing conditions without human operation. Automatic actuators are an effective way to make valve control less labor intensive, less expensive, and more efficient. Such actuators are especially valuable in hazardous environments where humans can’t easily or safely access equipment.

A valve actuator provides the following functions:

- Moves a ball, disc, or plug to open, close or adjust a valve

- Keeps the valve closed as needed, even under high pressure

- Positions the valve and snugly fits it into place

- Rotates the valve

- Works as quickly and effectively as the application demands

- Swiftly moves valve to a predetermined default open or closed position in the event of power loss or emergency

Automatic valve actuators rely on either pneumatic, hydraulic, or electric power:

Pneumatic actuators use highly pressurized air to move valves. These actuators can be either fully automatic or semi-automatic. Pneumatic actuator benefits include:

- Fast operating speed

- Minimal fire danger

- Relatively low costs

- The ability to continue functioning during electrical outages

Hydraulic actuators rely on highly pressurized fluid—usually water or oil—to move valves. Like pneumatic actuators, hydraulic valves can be either fully automatic or semi-automatic. Hydraulic actuator benefits include:

- Greater power than is typically available from pneumatic actuators

- Highly precise valve control

- The ability to take in a small amount of input pressure and convert it into a large amount of output pressure for valve adjustment

- High energy efficiency

Electric actuators use an electric motor to move valves. These actuators can be manual, fully automatic, or semi-automatic. Electric actuator benefits include:

- The ability to handle low temperatures

- High torque

- Consistent speeds and ability to readily adjust speeds

Vane or rack-and-pinion actuators are typically available in pneumatic or hydraulic versions. Rack-and-pinion actuators work well when high speed, low wear, and long actuator life are priorities. Vane actuators are limited to lighter loads and medium speeds, but are ideal for small spaces where room for the actuator is limited.

Automation Services

Whether you need a new automatic valve control system or want to retrofit existing valve controls, Erdmann Corporation can create a system that will suit the unique needs of your operation. Our expertise includes:

- Back pressure valves

- Pneumatically actuated two- and three-port valves

- Positioners

- Programmable electronic controllers

- Pneumatic transmitter controllers

- Pressure reducing valves

- Rack-and-pinion, vane, and electric actuators

- Safety valves

- Self-acting temperature control valves

Valve Automation and Erdmann Corporation

Erdmann Corporation has nearly 80 years of experience as a pipe, valve, and fitting distributor. We work with clients in diverse industries including chemical, petro chemical, distillery, sanitary, food, pet food, water and sewer, cement, mining, oil and gas, refining, pharmaceutical, marine LNG cryogenic and power plants. Erdmann will listen carefully to your needs and create a custom valve control system that meets them exactly.

Contact us today to learn more and discuss how we can work together.