What Are Steam Traps?

Steam traps are valves that remove the buildup of water residue—i.e., condensation—in steam systems. As these components are designed to recognize the difference between steam that should be present and condensation that should be removed, there’s minimal risk of losing steam power. Systems can also employ multiple steam traps to allow for more fine-tuned control and condensation removal.

Condensation buildup left unchecked within a steam system can significantly affect the system’s structure and performance over time. Consequences include:

- Corrosion throughout the system’s interior

- Increased pressure and the development of water hammer

- Lower or inconsistent product quality

- Poor heat transfer

There are a variety of steam traps available, each of which is suited for different applications or systems. At Erdmann Corp., our expert team can help you find the right steam trap to fit your facility’s needs. We also have full-service custom manufacturing capabilities to ensure your new or existing steam system has proper protection.

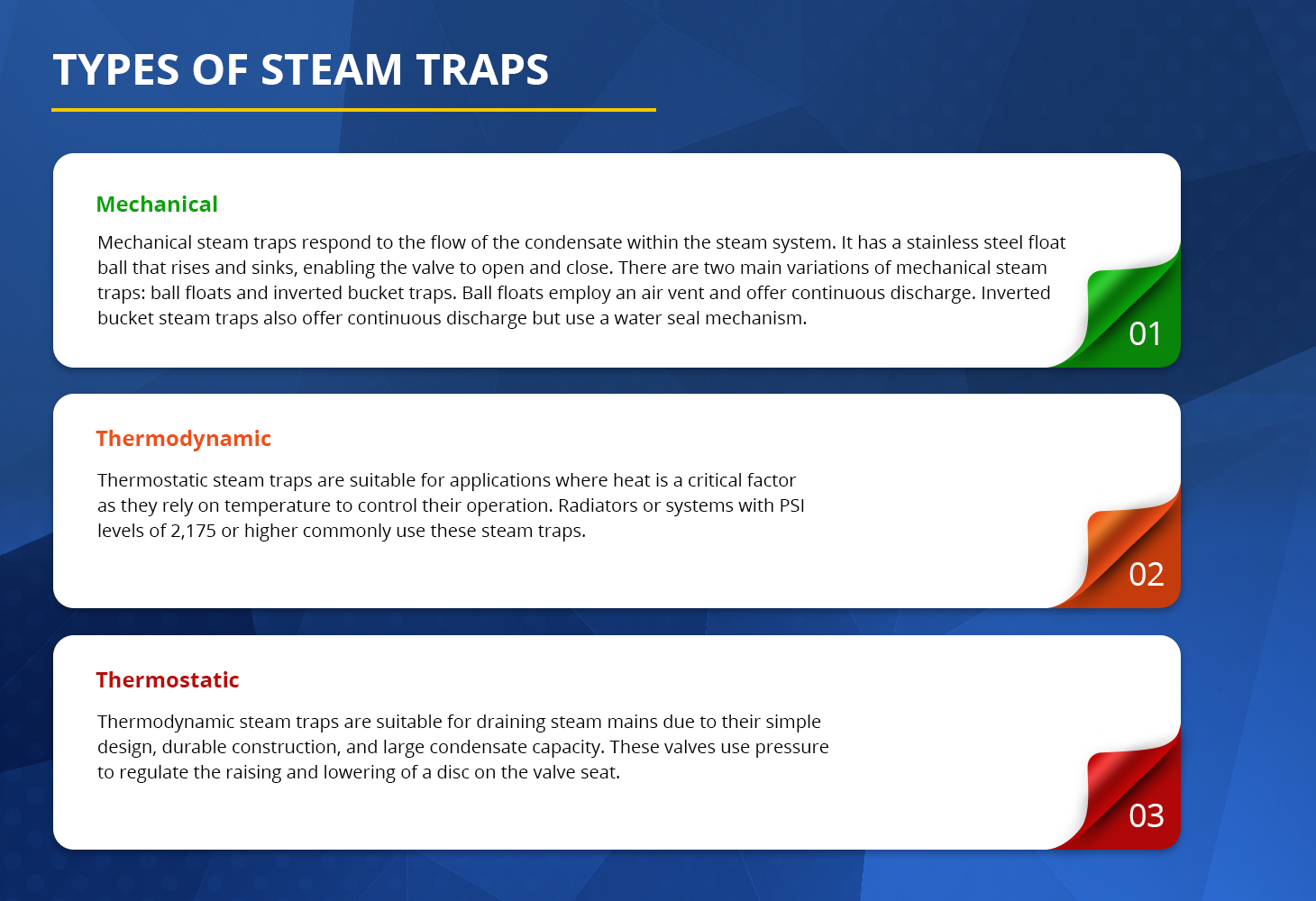

Types of Steam Traps

When selecting a steam trap for your system, it is important to understand the differences between the types available. Some of the most common types of steam traps include:

Mechanical

Mechanical steam traps respond to the flow of the condensate within the steam system. It has a stainless steel float ball that rises and sinks, enabling the valve to open and close. Since the levels of condensate present in the trap control the ball’s movement, this type of steam trap is highly precise.

There are two main variations of mechanical steam traps: ball floats and inverted bucket traps. Ball floats employ an air vent and offer continuous discharge. Inverted bucket steam traps also offer continuous discharge but use a water seal mechanism.

Thermodynamic

Thermodynamic steam traps are suitable for draining steam mains due to their simple design, durable construction, and large condensate capacity. These valves use pressure to regulate the raising and lowering of a disc on the valve seat. Upon startup, the incoming pressure forces the disc and condensate up, allowing for the discharge of air. As hot condensate moves through the trap, it generates flash steam, temporarily creating a low-pressure pocket that pulls the disc back down. The pressure of the steam locks the disc in the lower position to prevent any further leakage.

Thermostatic

Thermostatic steam traps are suitable for applications where heat is a critical factor as they rely on temperature to control their operation. Upon startup, cool condensate makes the thermostatic element in the part contract. This, in turn, opens the valve head to allow condensation to escape. Once the temperature increases and the system fills with steam, the element expands to close the steam trap. Radiators or systems with PSI levels of 2,175 or higher commonly use these steam traps.

Steam Traps From Erdmann Corp.

Since 1933, Erdmann Corp. has served as an industry-leading provider of valves, actuators, process piping and steam specialty products, including steam traps. We carry a wide range of high quality, high performance products, including ball, butterfly, diaphragm, gate, globe, check and plug valves from well-known manufacturers. For customers with specialized system or application requirements, we offer modification capabilities—including custom sizing, assembling, testing, and serialization—to tailor products to their unique needs. Regardless of your steam system needs, our expert team can help you find the right steam trap for your application.

We’re proud to serve the following industries:

- Cement

- Chemical and Petro Chemical

- Distilleries

- Food and pet food

- Power generation

- Sanitation

- Water and wastewater

- Pulp and Paper

- Mining

- Pharmaceutical

- Oil and Gas

- Marine

- Refining

- LNG – Cryogenics

- Nuclear

Contact Erdmann Corp. Today

Steam traps protect steam systems from potential damage due to prolonged exposure to condensate, such as inconsistent heat delivery and corrosion. As ensuring the performance of your equipment is key to remaining competitive in the industry, choosing the right trap is essential.

With over 90 years of experience providing valves for industrial systems, our team has the skills and knowledge to provide you with the optimal steam trap for your company’s system. If your company needs full-service custom manufacturing or access to a large inventory of valves, we’re here to help. Contact us to learn more about our products and custom manufacturing capabilities, or request a quote to get your order started.